SURFACE

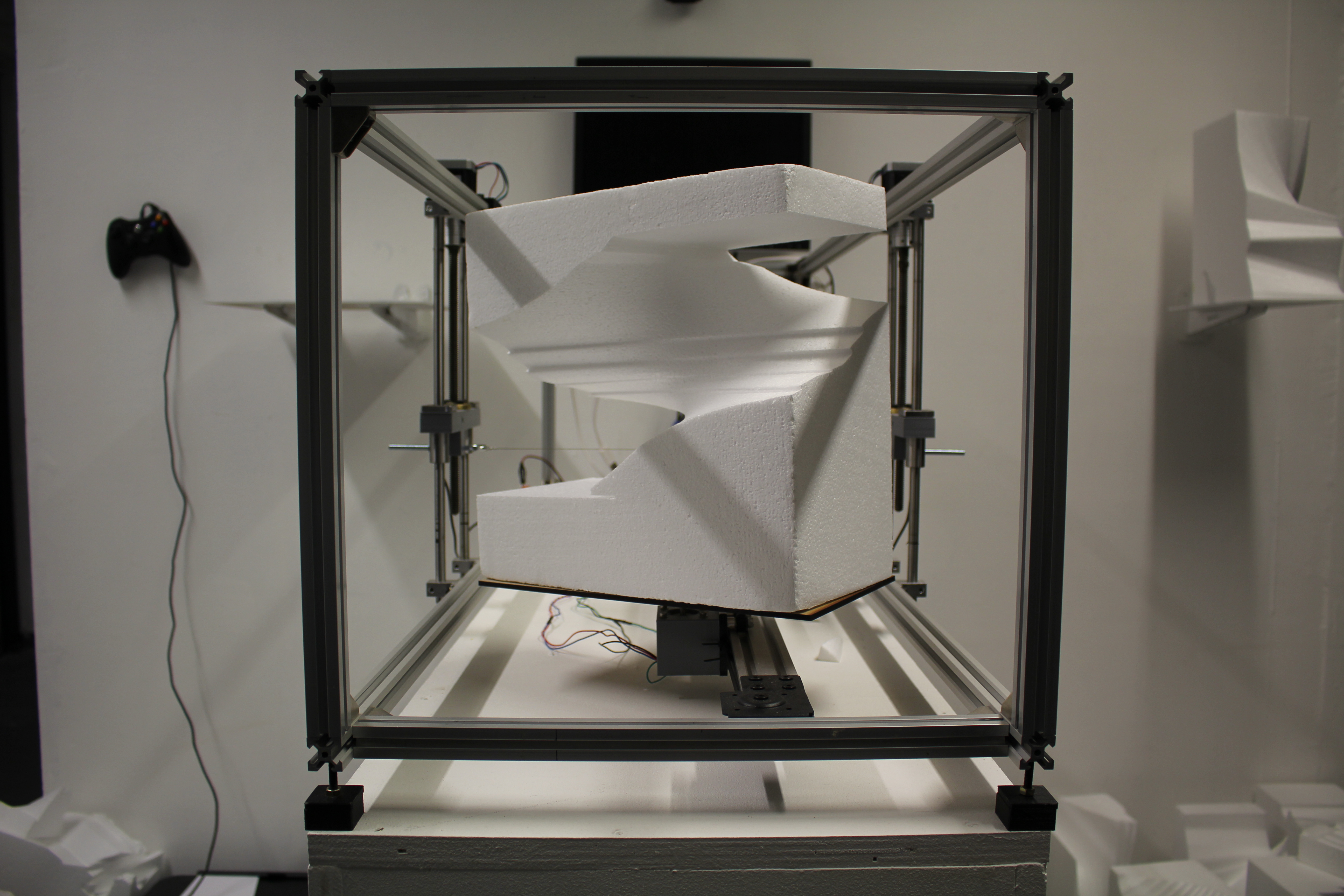

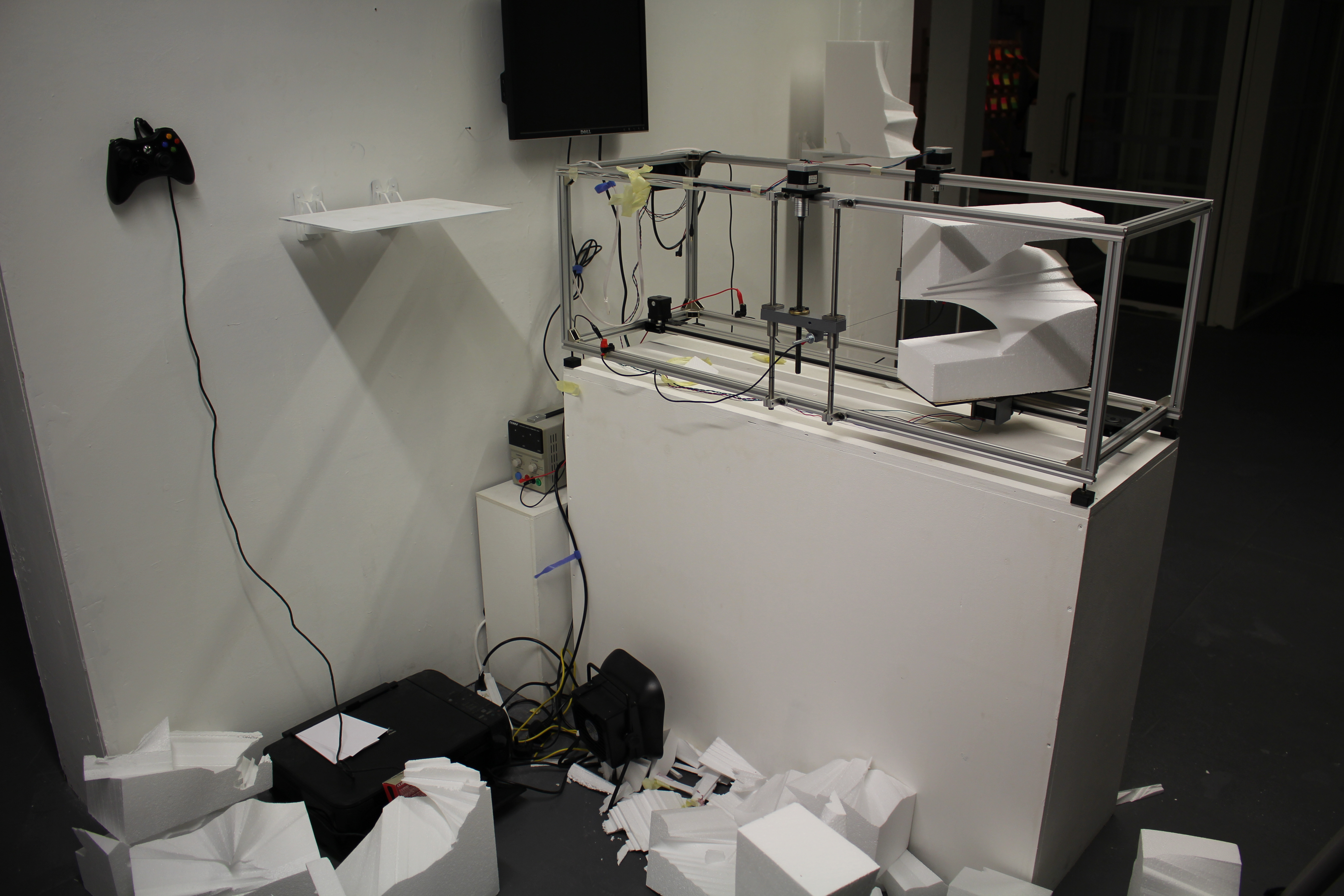

Surface is a intuitive sculpting instrument that cuts foams using multiple axis hotwire controlled by xbox controller

by: Freddie Hong

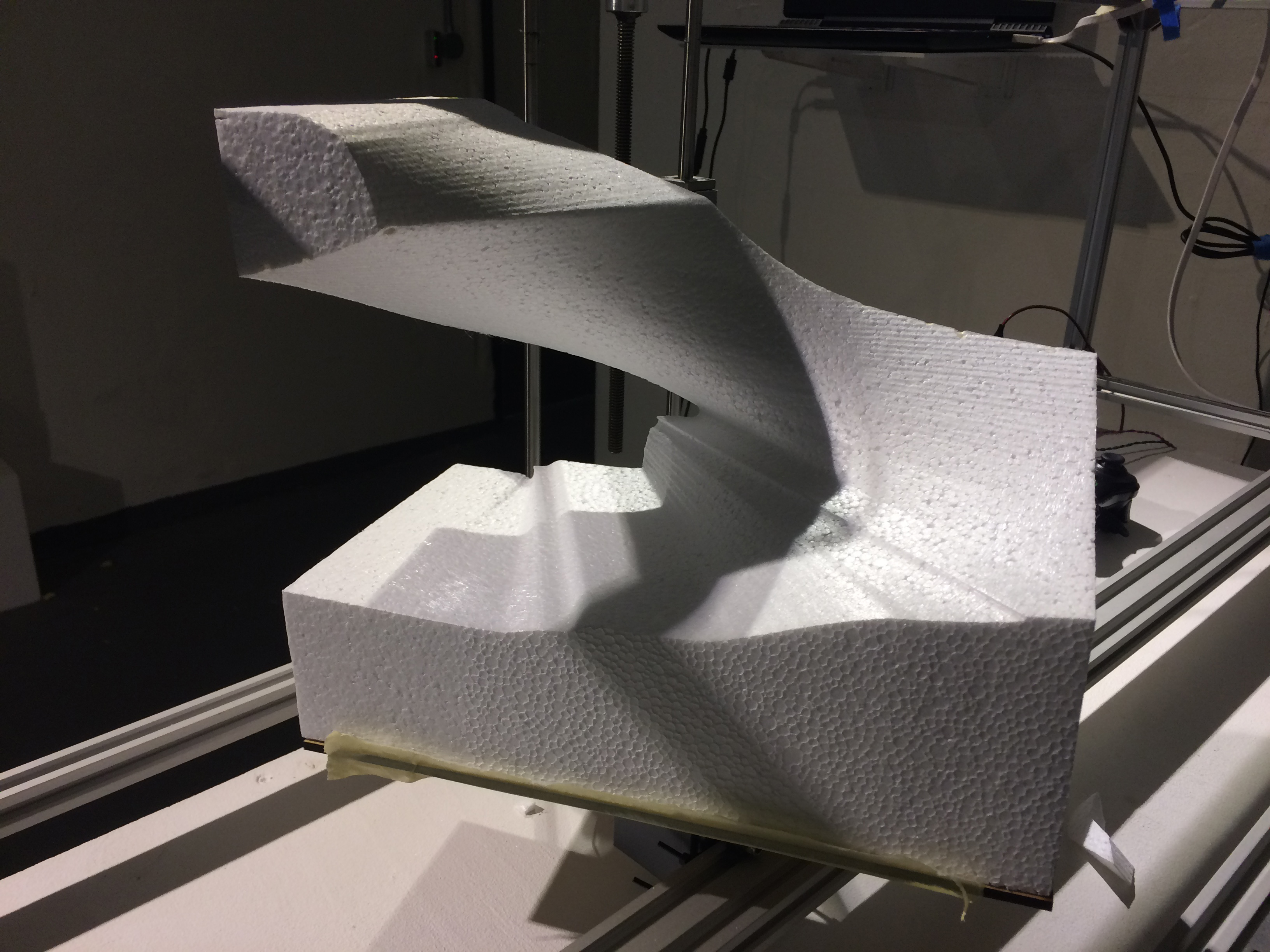

Surface is a machine that like other CNC devices, such as routers and 3d printers, allows the users to construct different geometries. However, differing from already existing CNC devices Surface is run by your intuition rather than pre-drawn digital geometries, challenging the ambiguous boundary between analog and digital. With Surface, users can produce different geometries using xbox controller. Surface uses hot wire and styrofoam blocks to construct the shape in a subtractive method. Users can witness and make alterations to their shape as the cutting happens, and unlike other conventional digital fabrication, what has been cut cannot be repeated perfectly. Only through mastering the technique can the user repetitively produce accurate modelings.

This work aims to introduce people to the joy of making shapes in a manner that does not require the users to have skills or even understand digital modelling. The idea of sculpting surfaces using a game controller therefore questions on the conventional compuatational aided method of describing and drawing shapes. Could a geometry be described and notated with a command and a score instead of mathematical quantities such as an angle and dimension? The project instead uses a ‘musical score’ that believes to be more sucessful notation in describing the geometry.

Discussing further about the computer aided geometries, while the computer is only a tool that eradicates mathematical limitations involved in an algorithmic process, it has significantly eased the process of calculation and thus contributed to the widespread of complicated geometries in design. The use of complex curvilinearity has become ubiquitous with an aid of advanced parametric softwares, and it is no longer relevant to discuss the sculptural quality purely on the basis of optical perspectives.

Computers can now calculate any curves that joins two independent points on Cartesian coordinates and produce accurate and organic looking geometries that does no longer require training or process based developement but a mere clicking and alteration of parameters that arrives at its final form through continuous automation which ends once it is has become satisfactory to the designer. In time of Gaudi this process would have required sleepless nights to calculate and physically model through plaster models and wires that involves hand-on tools and instruments specially developed for the targets geometries.

Through invention of an instrument that has its specific charactersitic in the shapes which it can sculpt, just like a pottery table with an aid of compuational technology, I wanted introduce a traditional method of constructing curve-linearity that exsisted since Gaudi's time through manner that overlaps between analog and digital.

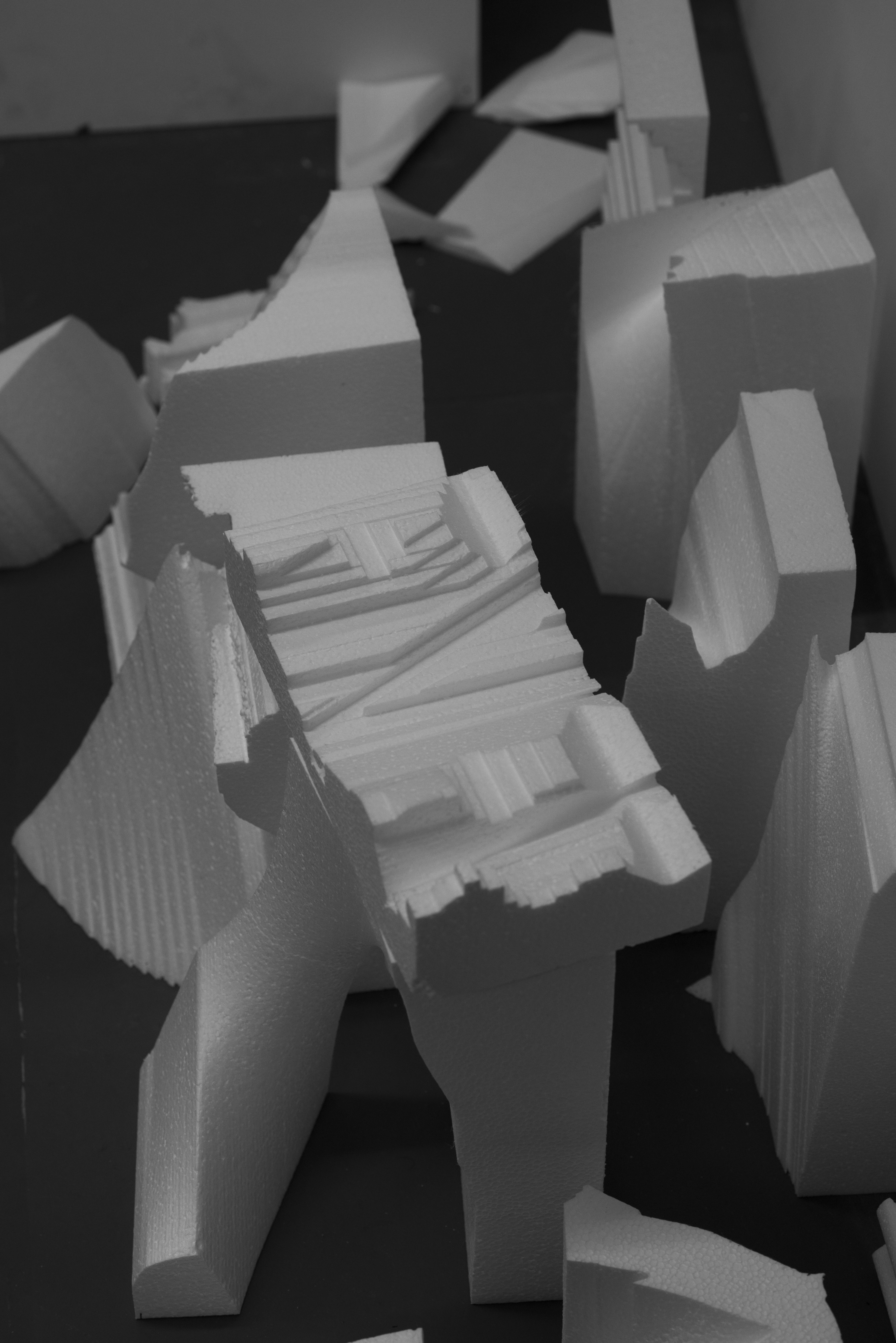

Surface was exhibited as a workshop rather than a static display as it was vital to have people actively invovled in the process of making. People were given short introduction to how the machine works and the process of sculpting was entirely left to them. Because the users had a direct control of the machine and had visual feedbacks on how the foam was cut it was entertaining to watch how users quickly gained more confident and became playful with the instruments.

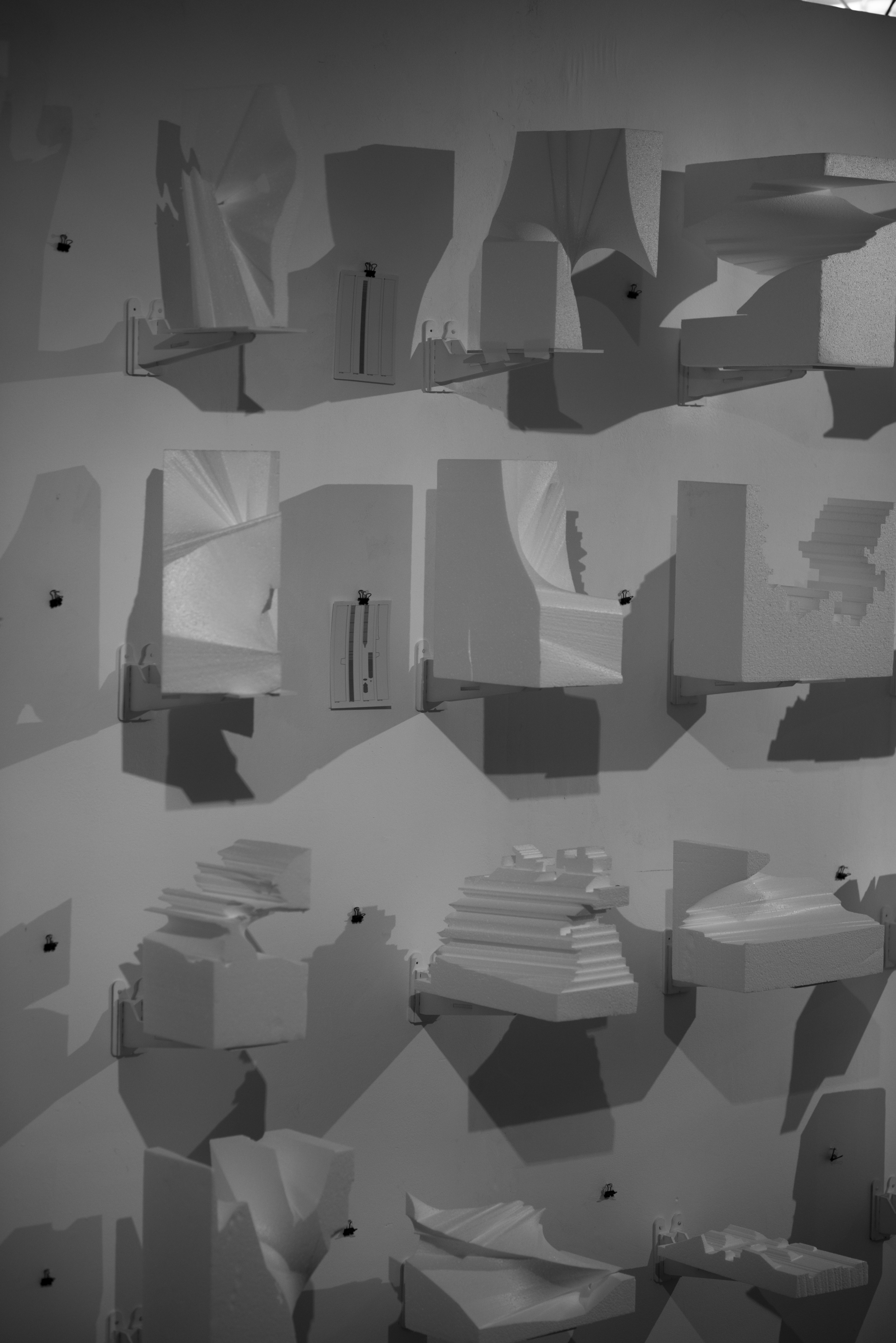

One side of the wall was the workshop and the other side was the display. Once the user completed sculpting the foam and happy with the result, they would take the foam to the other side and display. At the begining the display hence started with mostly empty shelves but as the exhibition progressed it was soon filled with people's work.

Also as the cutting happens, the computer records the commands/motions of the user and produces notations that appear similar to musical scores. By studying the notation, users can attempt to re-create the same geometry or even improve the shape. Notations were then printed and exhibited next to the accordant foam.

There are 4 commands to the controller, Left Turn, Left thumb, right thumb, right turn, these commands controls anti-clockwise rotation, x - axis, z - axis and clockwise rotation repsectively. Every time the notations reaches the top of the screen, program saves the vector and resets the canvas. If I was to recreate the geometry, I would refer to the notation rather than measuring the dimensions of already sculpted geometry.

Because all the geometries are cut from straight line, they can be referred as a ruled surface, which is basically a curved surface formed by continuation of the straigt lines. This ruled surfaces were first calculatable curved geometries that were critical basis of Gaudi's sagrada familia and Xenakis' Philips pavilion.

This machine runs on ramps board and arduino connected to 4 stepper motors. Then the arduino board is controlled by the openframeworks using ofSerial function which writes the input values from xbox into stepper's microseconds.

Further developement of this project will include the introduction of computed parameters such as perlin noise, that the motors will add organic movements on the user's command that even the user attempts to drive the hot wire in a straightline, due to the nature of the perlin noise, it will start constructing rough or rocky surface. In addition machine could have some pre-computed patterns or commands that users can utilise in their shapes. As the machine runs on multiple axis and has a capability of using various parameters it is easy to plug some additional playful parameters that would bring new characteristics to the process.

Addon

- ofxXboxController

References

- Mark Burry, Antoni Gaudi and Frei Otto: Essential Precursors to the Parametricism Manifesto, Architectural Design, vol. 86, no.2, 2016.

- https://freddiehongdesign.com/2017/04/25/drawing-surfaces-from-a-game-command/

- http://www.archdaily.com/157658/ad-classics-expo-58-philips-pavilion-le-corbusier-and-iannis-xenakis

- Joshua Noble, Programming Interactivity, pg 696, 2012