Algae Factory

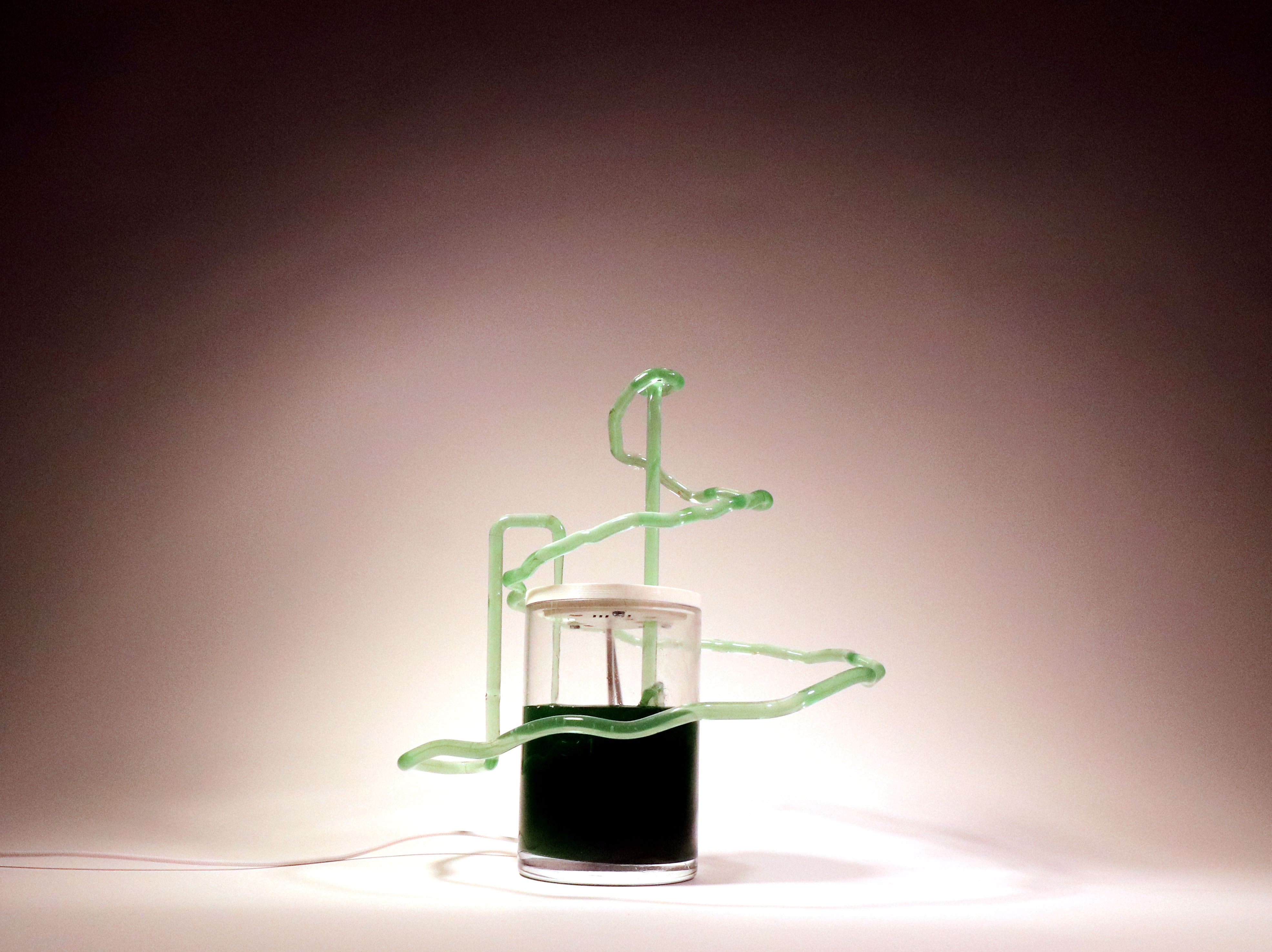

Algae Factory explores a domestic technique to produce clean resources of air and water. The architectural machine creates a self-regulating relationship between its ecology which in turn, produces a nutrient rich food source for its human co occupants.

produced by: Edward Ward

Introduction

The Algae Factory was created as a response to the Anthropocene. A domestic approach to food production using algae, specifically spirulina as a novel food source.

Concept and background research

After reflecting on work I had done for my previous modules and possible directions for my final project, I wanted to embody some of the theoretical concepts discussed in class with the physical production of a piece of work.

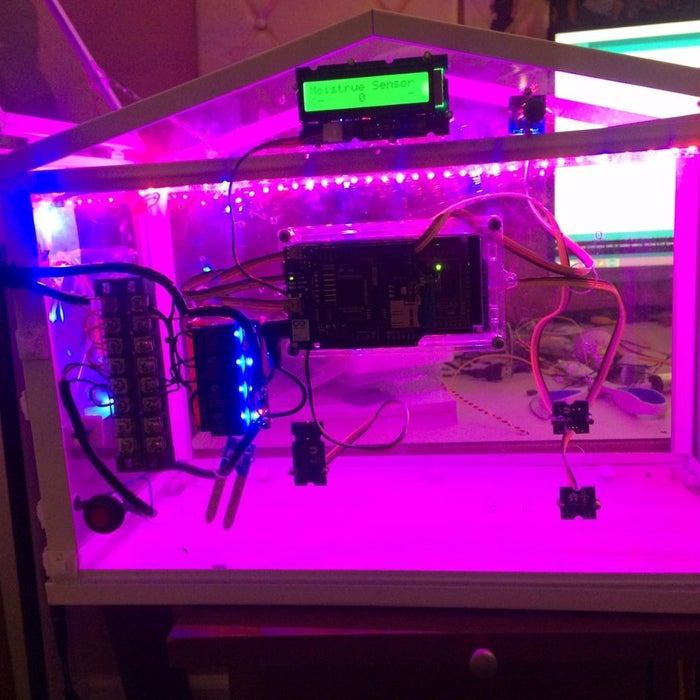

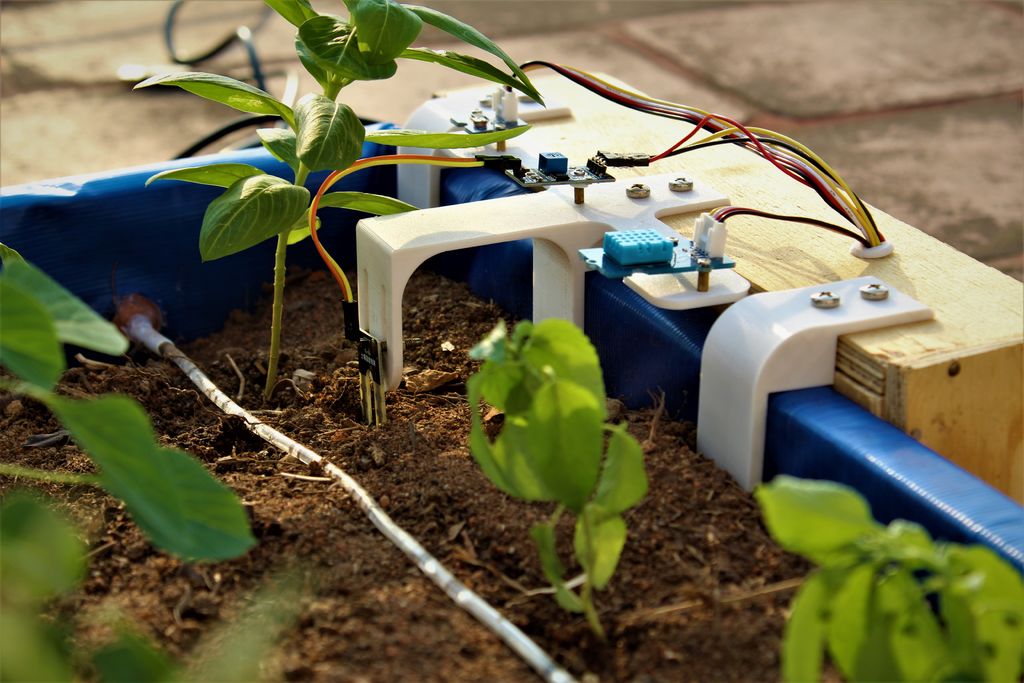

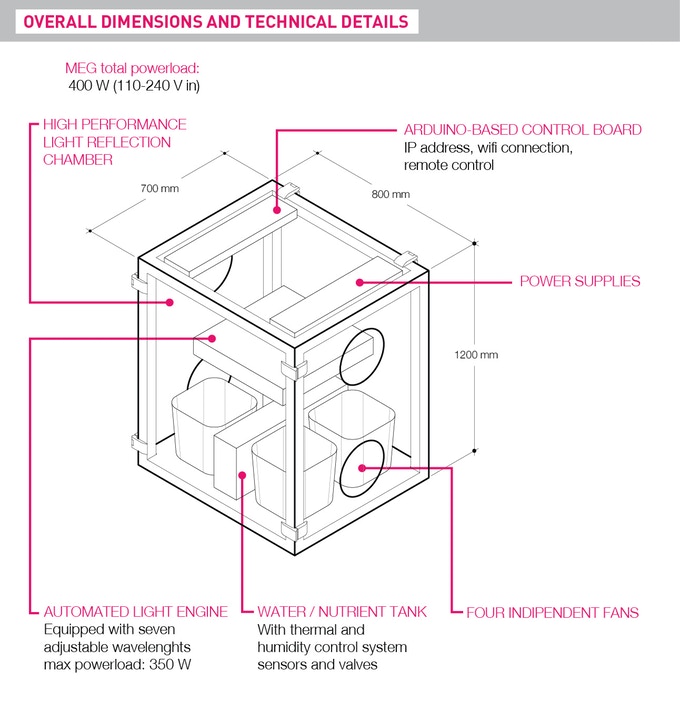

Throughout the project I had pitched my idea of creating a greenhouse that would be somewhat generative in its form and self-tending its plant occupants. I began to look at greenhouses for domestic application, exploring the connectivity between plants and technology both within the maker community and in the wider commercial world of products and services.

Their scope of sensing ranging from temp and humidity, moisture sensors and automatic grow lights. I began to research more critical projects that explored the relationships with humans, nature and the environment. This led me to work of Theodore Spyropouos, Claudia Pasquero and Hyphen Labs.

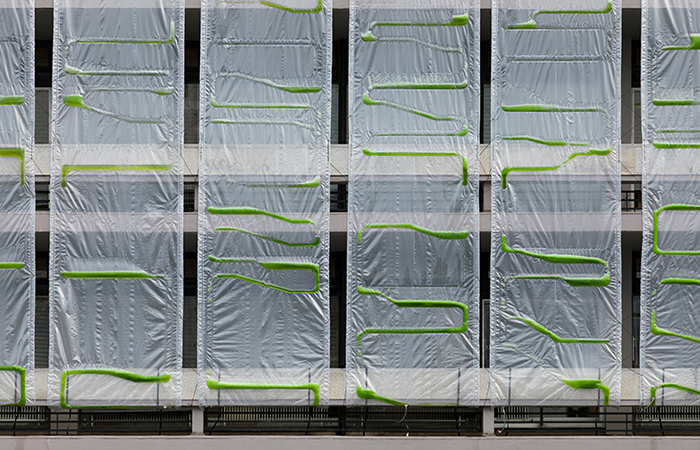

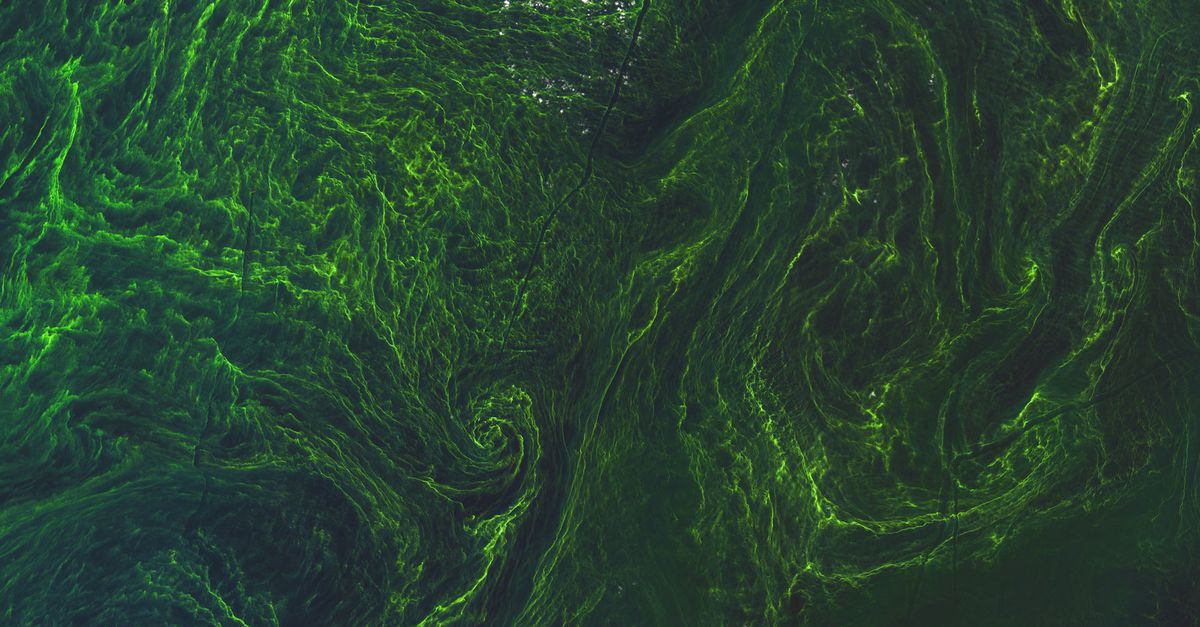

A question asked was what food would I grow, as that would determine what the form and function of the greenhouse would be, one of the threads that stuck was the ideas of using Algae as an approach to food production, research suggests that it is nutrient packed, easy to grow and harvest. It also functions as a contemporary approach for facing a range of the concerns food production stability, the Anthropocene, and scale of production both domestic and commercial.

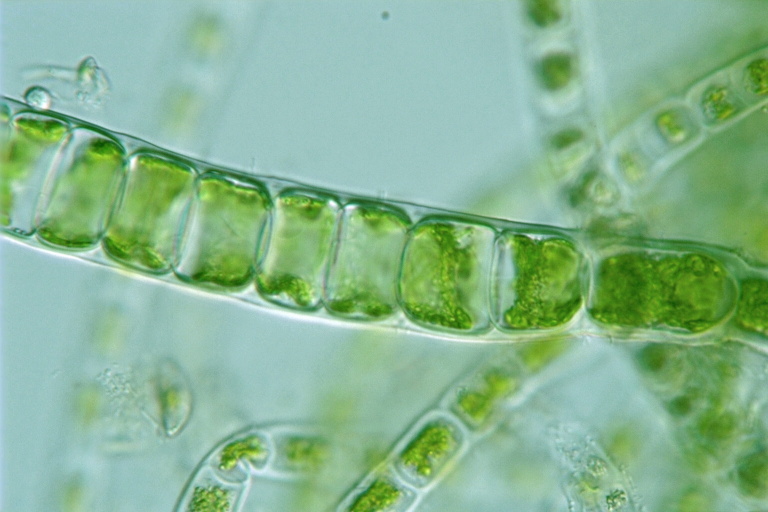

My designs moved forward as I explored these issues through the forms of the algae. Spirulina covered all the necessary requirements for food production for human sustenance and was also a source of inspiration for the form and function of the factory by examining the microscopic physical form of spirulina. Using images of spirulina and commercial algae farms I created an algorithm that would produce a network of tubes that would then the basis for the biosphere that would both house and cultivate the spirulina while referencing the natural forms of the algae.

Technical

Using processing I wrote a sketch to produce spiral forms with each point of the vertex having a random velocity that would break up the 2D structure and take the forms of the algae / spirulina cells as seen under the microscope. I drew the curve through the points using the curve vertex – but noticed they began in intersect with themselves which would not be suitable to manufacture. A rudimentary set of collision detection rules were implemented using if statements and measuring the distance between the points and their neighbours. Whilst this works for the points – it does not work on the curve itself – this is something that should be fixed in future development. After a few iterations, the sketch is saved as a DXF file – ready for further work.

I still need to get the computed form fabricated in a way that would enable it to work as a functioning farm so continued to experiment with acrylic tubes and 3d printing junctions, CNC machining formers. I quickly found out that the typical processes of bending tubes don’t lend itself to complex geometries which collapsed onto themselves, kinks, bubbles and discolours.

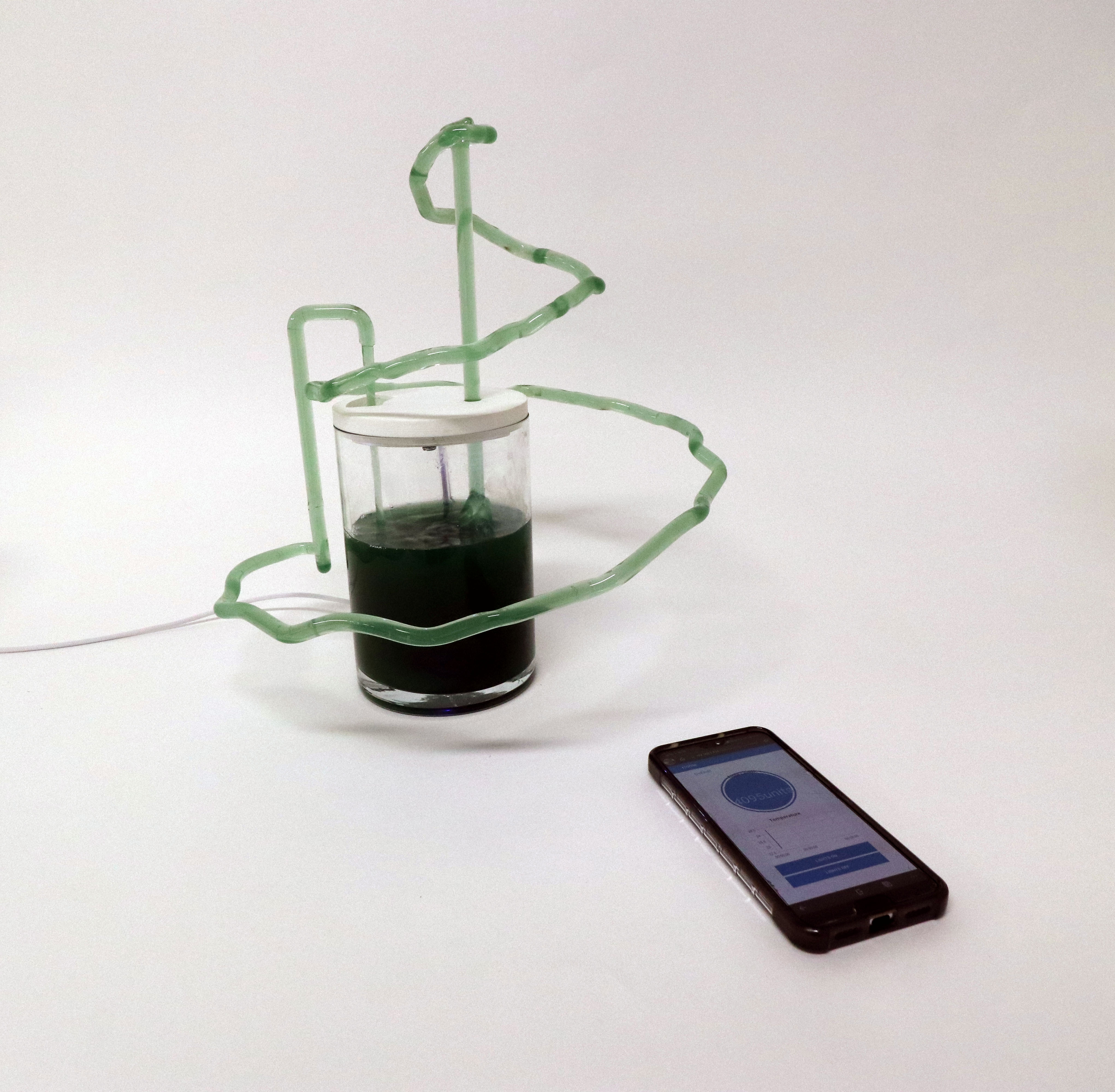

I researched glass blowing and found a local neon sign fabricator. This seemed a great match given the complexity within a neon sign, hopefully it could be translated to the artwork. After much deliberation and conversation with the fabricators, the original scope of the project was scaled back from several spirals at 1.5m diameter to a more manageable 3 spirals at 300mm.

The fabricators, David and Bill, spend the day creating the work with near millimetre precision to the former, in contrast to the production of the junctions where it interfaces with the lid, vase and pump which were designed and interpreted on the fly.

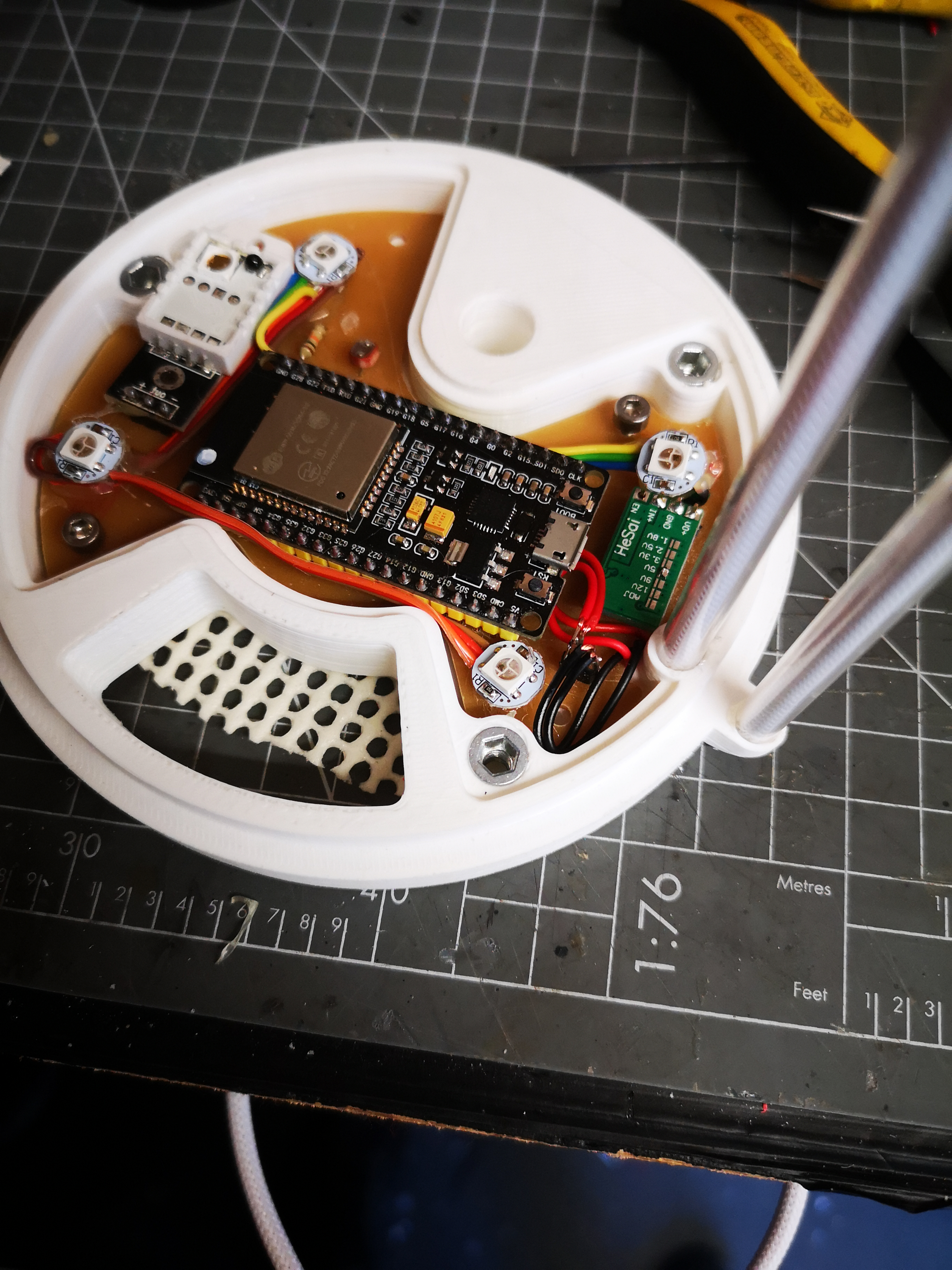

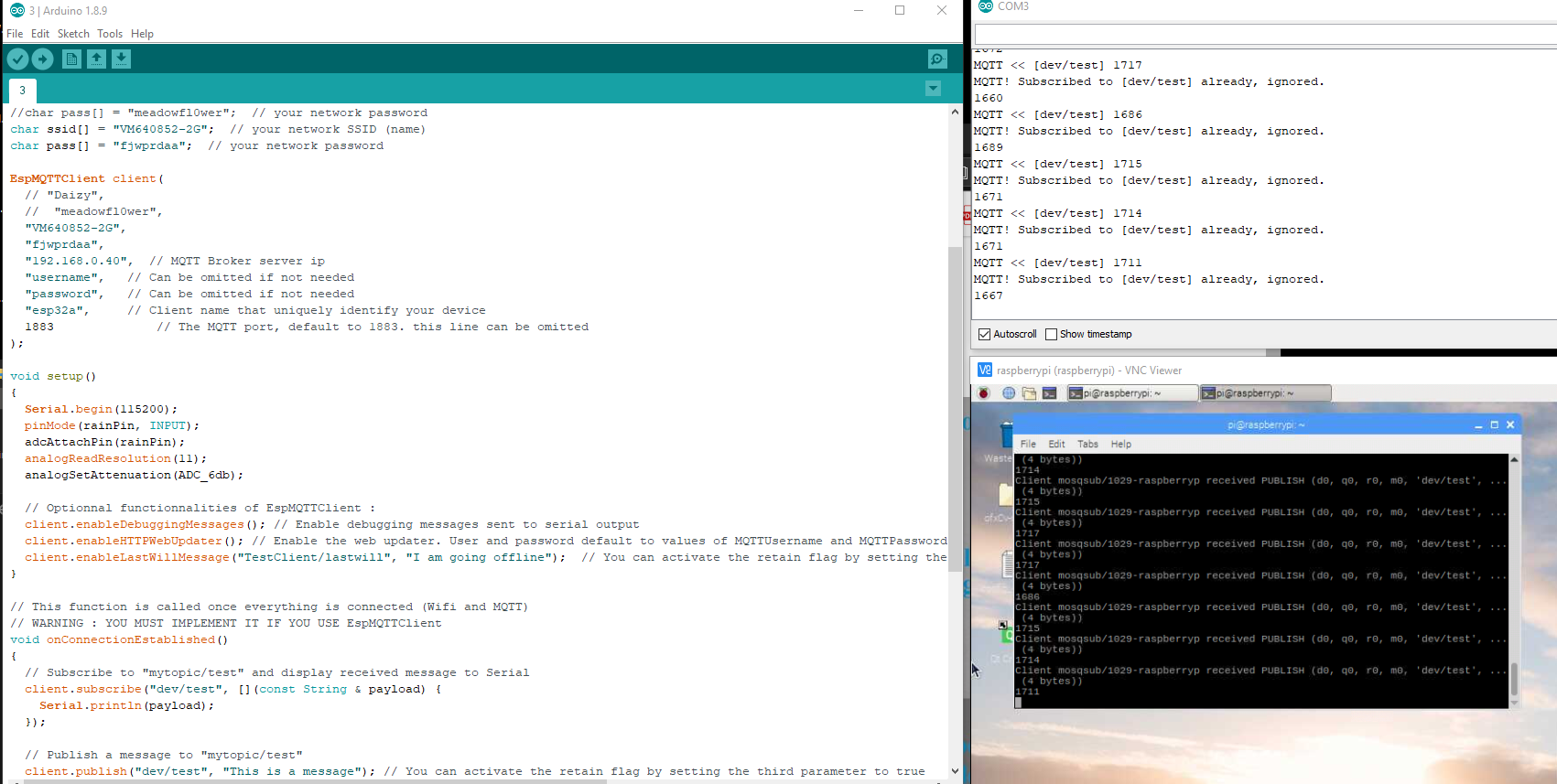

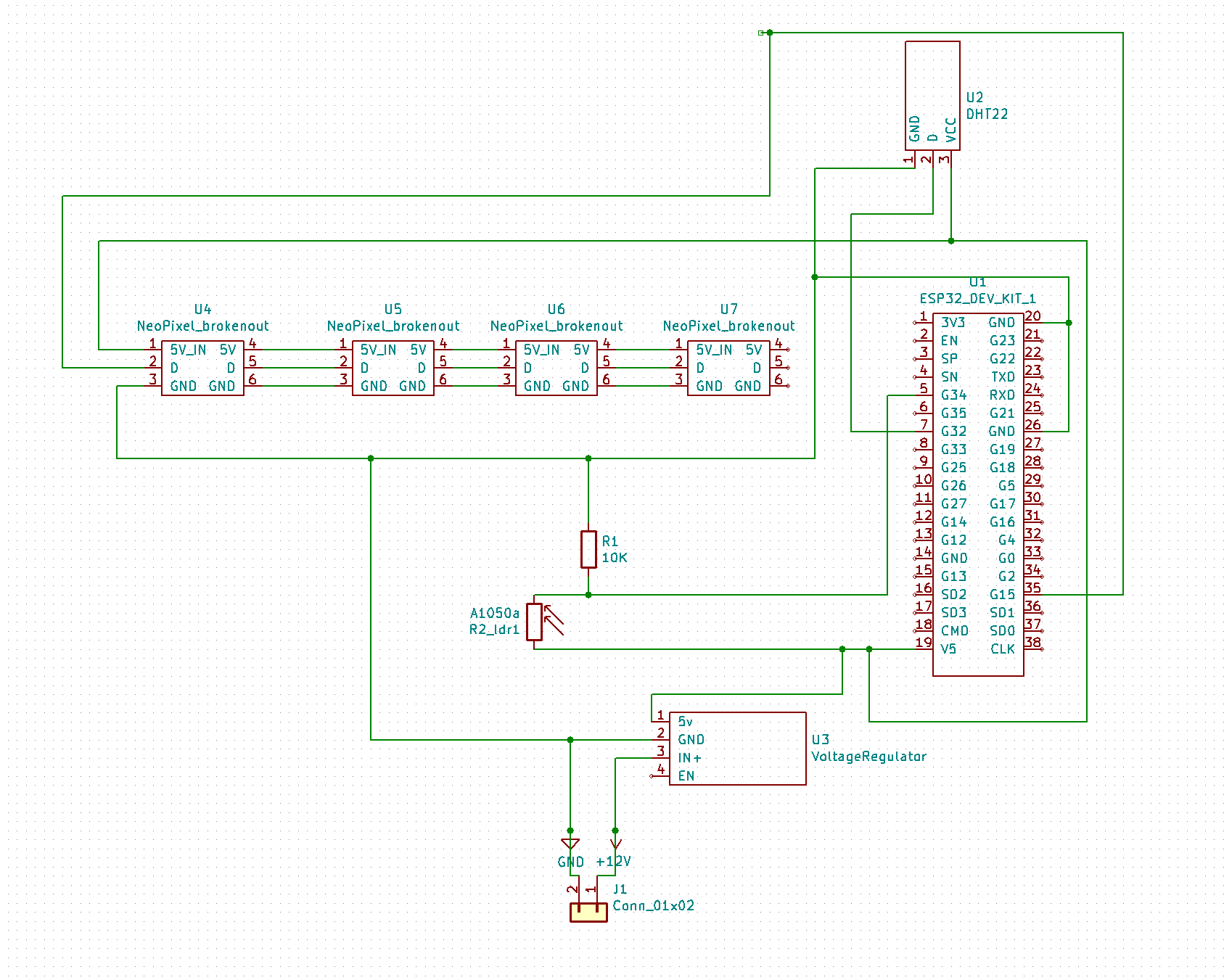

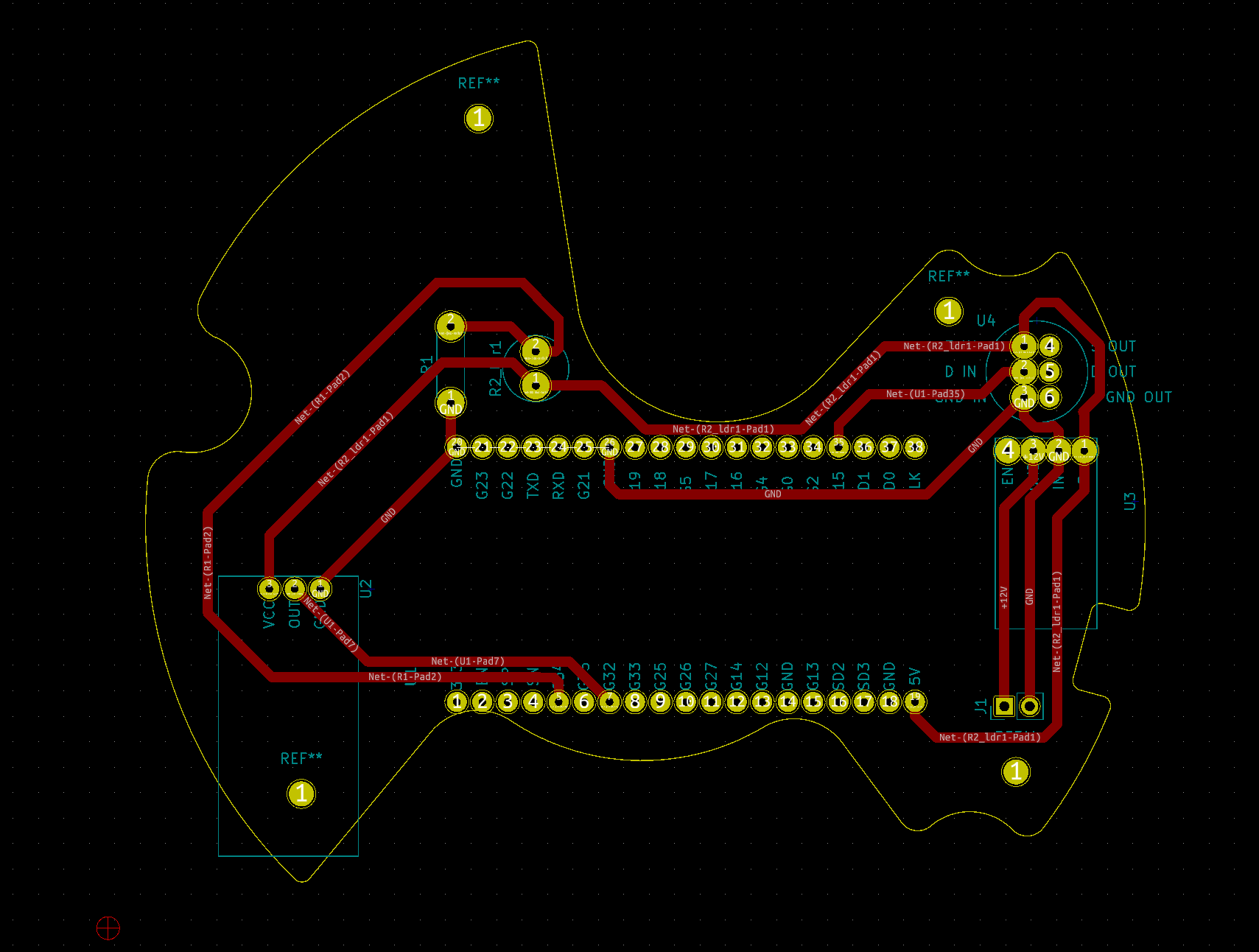

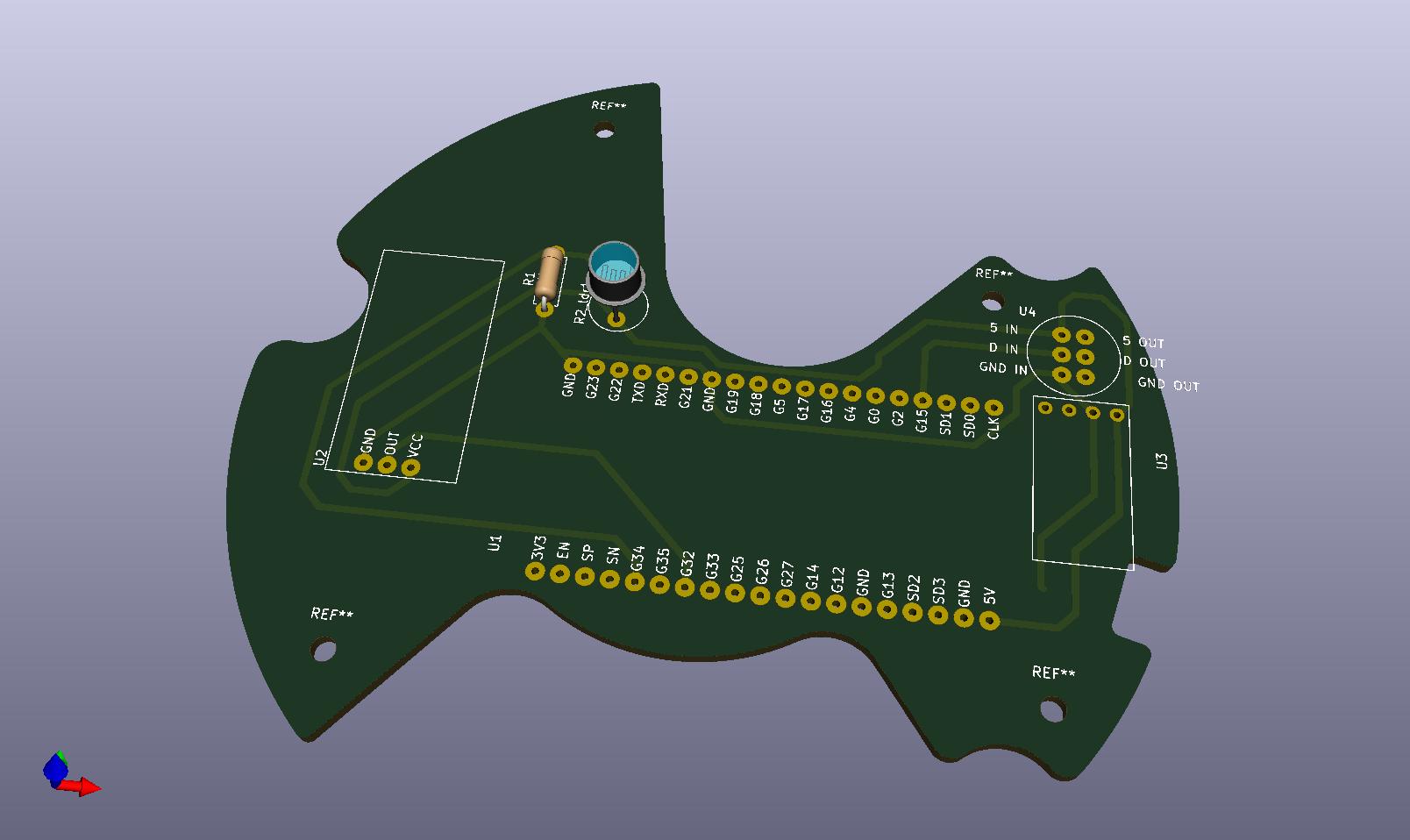

As the fabrication was now complete and with a week to go, I was able to focus on the connectivity of the factory to a user’s device as per the original aim of the work. As the form had changed significantly from a garden scale object, to a 1.5m spiral, to now a 300mm spiral, I scaled down the functionality and scope of the embedded device – it now contained a light dependent resister (LDR), 4 x Neo Pixels and a temperature and humidity sensor (DHT22). I booted up an ESP32 using the Arduino IDE and integrated the sensors and installed the ESP32 libraries which enabled me to use the pub/sub examples to connect to the raspberry pi, which in turn connected to a Node-Red sketch that enabled me to see the sensor data from a smartphone / tablet. This was all rounded off with the creation of a custom PCB, housed in the underside of the lid of the work.

Future development

Feedback I received during the viva offered suggestions of displaying the work with more of an exploration of the processes undertaken to arrive at the work, from the origin of the project through to the communication with the app. I would also like to add more complexity to the code that developed the tubes / form – for example, no intersections of the curves and an auto generating structure for the formwork. The creation of an interface could be a nice interactive element on designing your own Algae Factory for your home.

Self evaluation

My intention was to create an emergent form that would respond to rules applied to it. These rules were intended to include data such as geographical location, and average levels of sunlight which would in turn inform the structure, or the amount of spirulina that is required to be produced, which would inform how many tubes were produced. I went into the program thinking there would be at least a couple of strands that would grow towards the sun path and take the form of the spirulina micro-organisms. After several iterations of using random as a placeholder, I was able to incorporate ofxSunPath into the sketch and use real data to inform the scale, rotation and direction of the growth. Things were looking suitable, however there was a tension in how this was to be realised as a physical object, either as a 1:1 piece or as a prototype for the exhibition. I began to experiment with types of acrylic tubes and 3D printing in clear filament on some example forms that I created in grasshopper following a tutorial found online. A serious wall was hit when I found that I was unable to export a polyline in 3D from open frameworks.

I converted the program to use vertices and ofMesh but still unable to export. With time ticking, I re-wrote the program using processing knowing that the DXF exporter works with 3D vertices. At this stage I was beginning to really panic as I was over half way into the project but with nothing to show other than a few experiments! Recreating what I had in open frameworks didn’t faithfully translate into processing. I created a series of points and put those x, y, z positions into an array, but was unable to get a curve to connect from its previous position to its new position. This meant that the curves didn’t resemble faithfully the work from open frameworks. After some days of experimenting and exploring examples, I compromised on the form as it appeared in open frameworks as the new forms honoured the original designs I had sketched, so I was happy to progress in refining the forms to fit the original aims of the project.

Overall I am very happy with the outcome of the project. I was able to produce a prototype based on what I set out to produce, an algae factory. I worked many hours throughout the project from the beginning to its end. I was able to incorporate all the functionality and features that I set out to achieve. My regrets for the project, as usual, is within the code itself for the piece – I always feel that it is not at a sufficient level for where I should be at – which essentially makes me freeze and unable to progress. With that said, I try to pick up points where I could, relying on existing but refined skills in the design and fabrication of the work. I am particularly happy with the MQTT / circuit board fabrication as that was something I tried to do for one of my physical computing modules but at the time found it sufficiently complicated and non-compliant! This time, it worked, albeit through gritted teeth again.

I learned a bunch about how I work under pressure and the requirements of a practitioner if they were to be freelance, such as timeframes, expectation, cost factors etc. Whilst I think I gave the project my all and can multitask within the project, I’m not sure I was able to focus on much else around it, such as other projects / upcoming jobs (as I’m part time) which is something that I need to work on!

References

Ecologicstudio.com. (2019). :: EcoLogicStudio ::. [online] Available at: http://www.ecologicstudio.com/v2/index.php [Accessed 13 Sep. 2019].

Hyphen-labs.com. (2019). moss voltaics. [online] Available at: http://www.hyphen-labs.com/moss-voltaics.html [Accessed 13 Sep. 2019].

Instructables. (2019). Instructables Search Results. [online] Available at: https://www.instructables.com/howto/garden+arduino/ [Accessed 13 Sep. 2019].

The Bartlett School of Architecture. (2019). Prof Marjan Colletti. [online] Available at: https://www.ucl.ac.uk/bartlett/architecture/prof-marjan-colletti [Accessed 13 Sep. 2019].

YouTube. (2019). MQTT Network Controller. [online] Available at: https://www.youtube.com/watch?v=VSwu-ZYiTxg&feature=youtu.be [Accessed 13 Sep. 2019].